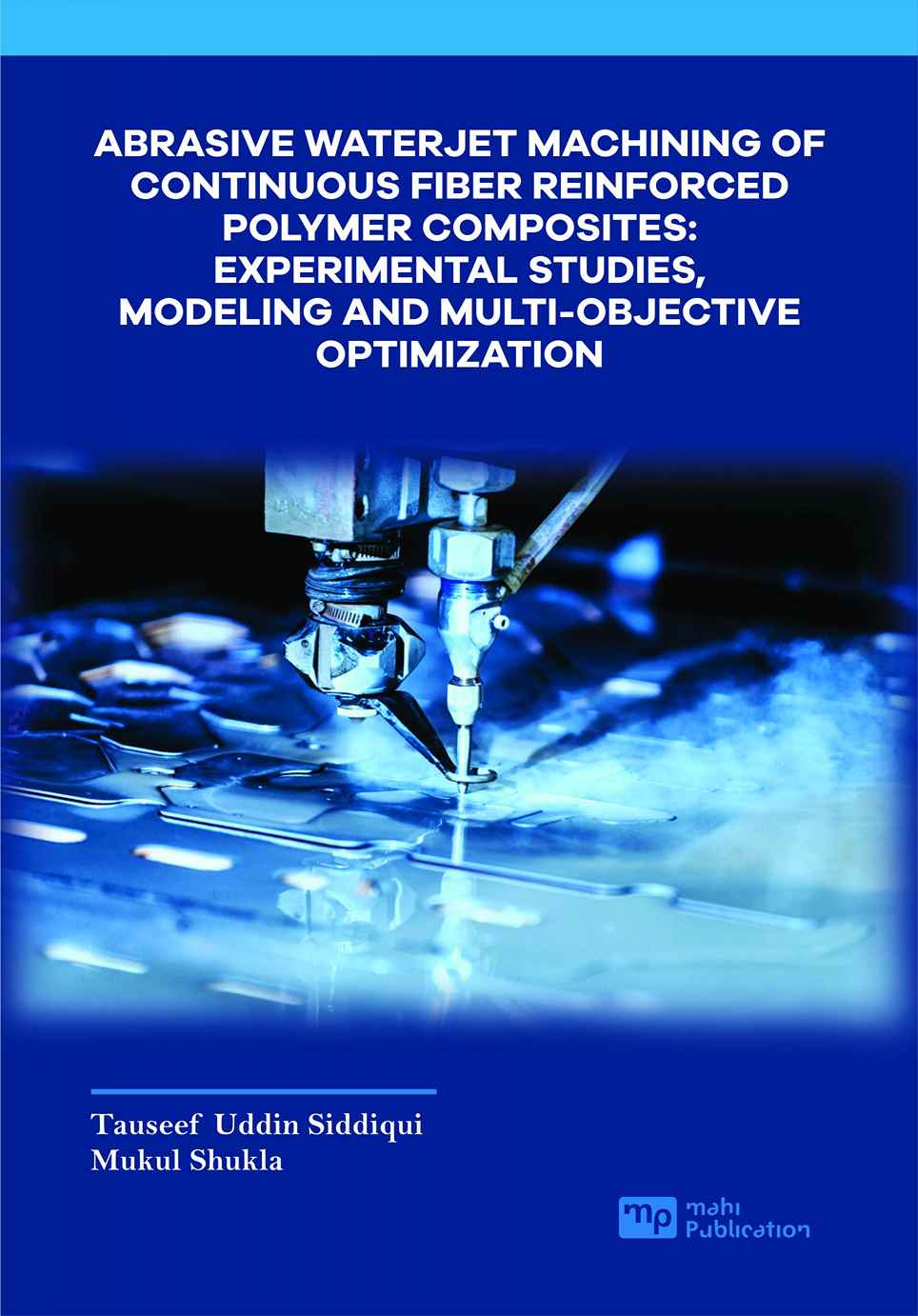

Abrasive Waterjet Machining Of Continuous Fiber Reinforced Polymer Composites: EXPerimental Studies, Modeling And Multi-Objective Optimization

Authors:

Tauseef Uddin Siddiqui,

Mukul Shukla,

Format: Paperback | Genre : Agriculture | Other Book Detail

Format: Paperback | Genre : Agriculture | Other Book Detail

Composite materials used today are at the leading edge of material

technology, with performance and cost appropriate to demanding

applications such as aerospace, marine, automobiles etc. Composite

materials outperform metals in terms of specific strength and specific

stiffness. In addition to superior structural properties, composites are in

many cases better in corrosion resistance, fatigue resistance, thermal

insulation, thermal and electrical conductivity, and acoustic insulation

than metals. Aerospace structures for example require high specific

stiffness and strength and a very high degree of dimensional stability

under a wide range of temperatures, which are encountered in space.

Because of a negative coefficient of thermal expansion of the carbon

fibers along their axis, aerospace structures can be designed such that a

zero-dimensional change is achieved over a wide range of temperatures.

These unique properties make the composites an obvious choice for both

military and civilian aircraft components. Military aircraft being more

concerned with performance than cost has witnessed the maximum

utilization of advanced composites. Fiber-reinforced polymer composites

are being used extensively in the primary and secondary structures and

control surfaces of military aircraft. Common components include wing

skins and substructures, rudders, flaps, vertical and horizontal stabilizers,

radome, rotors and blades and various access doors. Reinforcement fibers

are mostly carbon and graphite, but glass, aramid, and hybrids are also

used [Chawla, 08; Jamal, 09].

Book Also Available On

Share: